The supply chain for seed in Uganda: Where does it all go wrong?

Seed quality is a major concern in Uganda

Evidence from recent studies suggests low country-wide adoption of improved seeds by farmers. Farmers prefer to use home-saved seeds, indicating that they did not perceive the benefits of improved seed to be worth the cost (Tripp and Rohrbach, 2001; Remington et al., 2002; Sperling et al., 2008). This has been linked to several reasons, including limited market information, credit constraints, low social capital, but also concerns about quality, including potential on adulteration and contaminations of agricultural inputs in the local supply chain. For example, Bold et al. (2017) found that a random bag of fertilizer has significantly missing nutrients and, under certain circumstances, can lead to negative returns for Ugandan farmers. They also looked at yields from improved maize seeds and found a similar story.

One reason widely cited for low yields is purposeful adulteration of seeds by sellers along the supply chain. As a result, agricultural policy and programming has tended to focus on certification. However, little effort has been placed by the Government and the international community to improve the quality control of the seed supply chain as a whole. Current government certification and oversight of seeds has not proven to be adequate for ensuring farmers obtain good quality inputs. Rectifying these issues within the regulatory processes has not been successful to date. Neither seed companies nor input shops are well regulated and market failures have emerged, meaning that the access to optimal quality seeds is still very limited.

The Ugandan supply chain for seed is complex, involving multiple actors before the seed gets planted by the farmer

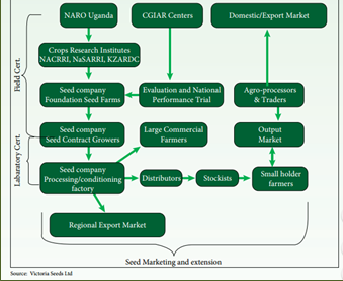

Figure 1. Seed supply chain in Uganda

Notes: The National Crop Resources Research Institute (NaCRRI), Namulonge, is the main supplier of breeder seeds to seed companies. The seed companies then multiply the seed at foundation farms or using contract growers. Company-produced seed or labeled seed is then packed and sold to farmers through a distribution network consisting of company outlets, wholesalers, and retailers.

A proof of concept to explore the seed supply chain: Lab testing of seed samples collected by mystery shoppers

This project expands recent work of researchers looking at the quality of agricultural inputs in Africa (Bold et al., 2017; Ashour et al., 2017; Ilukor et al., 2017). To diagnose where quality issues develop, we explore 21 varieties of maize across the supply chain.

To collect a representative sample of seeds - as if an actual farmer would have purchased those seeds - we employed a mystery shopper approach. A well-trained team of enumerators self-identifying as farmers purchased seeds from a census of companies at all levels of the supply chain, across three districts in the north, Arua, Kitgum, Lira, and the capital, Kampala.

The sample of seeds were then sent to testing facilities in Uganda for purity and performance examination. To identify how genetically similar the seeds were to each other (or in other words, to screen if any seed was adulterated or contaminated) the sample of seeds was shipped from Uganda to a laboratory in Australia to test for seed’s genetic purity. This set of tests are generally employed in quality assurance and regulatory compliance to guarantee seed’s trueness-to-type, freedom of contamination, and ability to produce normal and healthy plants in the field (Roos and Wianer, 1991).

Seeds were thus tested on three main indicators: (1) DNA tests, or how similar observations are across to each other; (2) physical tests or the percentage of the seed that contains stones, dirt, or sand; and (3) germination tests defined as the percentage of seeds that can germinate normally under standard conditions; vigor tests defined as the percentage of seeds able to germinate under suboptimal conditions and after storage; moisture tests defined as the percentage on wet weight basis.

Quality appears to be the main issue, not whether the seeds are pure. The results are consistent with mishandling and poor storage of seeds

The study does not find evidence of serious seed faking or adulteration. Instead, we find high levels of seed genetic and physical purity across all levels of the supply chain. Seed samples collected are genetically very similar to each other and on average presented good physical purity (above 99%), or good content of pure seeds (and absence of inert matter or dirt, sand, stones, sticks, and stems[1]).

We also do not find that average quality of seeds deteriorates along the supply chain. However, we do observe high variability of quality of seeds at the lower end of the supply chain. Tests scores highly fluctuates across observations with frequent extreme values. For example, some seeds only scored 4% in germination tests and some others 0 in the vigor tests.

Results from tests of vigor and moisture content, combined with high levels of DNA similarity, lead us to believe that the causes for low quality are most likely due to poor management in the downstream levels of the supply chain (wholesalers and retailers) that create poor storage conditions.

Monitoring mechanisms, collective action within stakeholders, and further exploration on seeds during storage and transportation are key for better seeds

Monitoring mechanisms should be targeted along the seed supply chain level, especially to wholesalers and retailers to assure quality. Although rules are in place, few resources are available for regulators, meaning that currently seed monitoring is almost non-existent. To guarantee high-quality seeds, Uganda’s Government and NGOs have devoted significantly large efforts on seed certification. E-labels[2], for example have recently been implemented to address the issue of counterfeit seeds. However, as we examined here, quality issues are likely related to poor conditions during storage and transportation. On top of seed certification, implementing complementary mechanisms, as regular quality control inspections, is key.

In addition, dynamic relationships between suppliers, farmers, and public agencies are crucial to improve commercial relationships. Collective action within stakeholders could start with seed companies working on the mechanisms to inspect quality (e.g. moisture), and then public agencies can monitor that quality policies are met along the supply chain at any district.

A note of caution is needed for these results. We were only able to trace the supply chain of maize in one year, and across three districts. The results are thus potentially limited in their application to other crops, years and districts. We are also limited in our sample size as we were only able to collect 120 samples in total. A replication of this proof of concept is needed in different regions, seasons, and years. This will allow to confirm the absence of counterfeit seeds more broadly. We also recommend further studies on the practices and conditions during seed storage and transportation. Future evidence is needed to determine conclusively what is driving low quality seeds in Uganda.

If the results we obtained can be generalized, it is possible they could significantly change the way policy makers approach the issue of low quality seeds in Uganda. If adulteration is not the problem, but instead storage and transportation are the major constraints to quality, money currently being spent on certification processes could be better spent. Future work will need to confirm this interpretation is in fact true.

References

Ashour M, Billings L, Gilligan D. Hoel J., Karachiwalla N. 2017. "Do beliefs about agricultural inputs counterfeiting correspond with actual rates of counterfeiting? Evidence from Uganda." In Press.

Bold, Tessa & Kaizzi, Kayuki & Svensson, Jakob & Yanagizawa-Drott, David. 2017. "Lemon Technologies and Adoption: Measurement, Theory and Evidence from Agricultural Markets in Uganda." The Quarterly Journal of Economics 132 (3): 1055-1100. doi:doi.org/10.1093/qje/qjx009

Ilukor, J., Kilic, T., Stevenson, J., Gourlay, S., Kosmowski, F., Kilian, A., Sserumaga, J., and Asea, G. 2017. "Blowing in the Wind: The Quest for Accurate Crop Variety Identification in Field Research, with an Application to Maize in Uganda."

Louise Sperling, H David Cooper and Tom Remington. 2008. "Moving Towards More Effective Seed Aid." The Journal of Development Studies 44:4: 586-612. doi:10.1080/00220380801980954.Tripp, D. Rohrbach. 2001. "Policies for African seed enterprise development." Food Policy 26(2001): 147:161.

Remington, T., Maroko, J., Walsh, S., Omanga, P. and Charles, E. 2002. "Getting off the seed and tools treadmill with CRS seed vouchers and fairs." Disasters 26(4): 302–315.

[1] On average, content of inert matter in the samples is less than 1%

[2] Enable consumers to verify the authenticity of seeds. Farmers scratch-off the label to reveal a unique code, then they send it via SMS to a number provided and receive back a message with the details on the product that confirms whether it is authentic.